Lathe - cycle-controlled

Machinelist: Lathe - cycle-controlled

Lathe - cycle-controlled

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

#1108-78102 · Lathe - cycle-controlled

SAEILO - Dialog A-50 - - - 828D SL + ShopTurn Siemens

Technical details

Lathe cycle controled VDF BOEHRINGER - DUS 560 / 3000

- Harry Vraets Machinery B.V.

- Gezellenstraat 2

- 3861RD Nijkerk

- Niederlande

-

+31 (0)332452145

-

info@vraetsmachinery.com

www.vraetsmachinery.com

#2039-11948C · Lathe - cycle-controlled

WMW-NILES - DP 4000 DP 5000 - - -

Technical details

4-jaw face plate Ø 3.150 mm modular lathe!

- Harry Vraets Machinery B.V.

- Gezellenstraat 2

- 3861RD Nijkerk

- Niederlande

-

+31 (0)332452145

-

info@vraetsmachinery.com

www.vraetsmachinery.com

#2039-11994CE · Lathe - cycle-controlled

WOHLENBERG - PT1 U1070 S111 - - - Alan Bradley 9-series

Technical details

3 Shear Bed, Carriage can bypass Steady Rest and Tailstock 6-position Sauter Turret 360 mm Capacity Self Centering Hydraulic Steady Rest 385 mm Capacity Rotaring Work Support (Used for Gun Barrels) 800 mm 4-Jaw Chuck Tailstock Quill diameter Ø 200 mm Tailstock Taper M.T. 6 Chip Conveyor

- Harry Vraets Machinery B.V.

- Gezellenstraat 2

- 3861RD Nijkerk

- Niederlande

-

+31 (0)332452145

-

info@vraetsmachinery.com

www.vraetsmachinery.com

#2039-12109C · Lathe - cycle-controlled

PADOVANI - Labor E 300 - - - Siemens 805

Technical details

3- jaw chuck diameter: 400 mm 4- jaw chuck diameter: 250 mm Fixed bezel diameter: 360 mmIncludes: 4 jaw turrets and coolant.

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03709 · Lathe - cycle-controlled

GILDEMEISTER - NEF 710 - - - Heidenhain

Technical details

The tech. Data are manufacturer or operator information and therefore for us not binding. We reserve the right to prior sale; it apply only our business and conditions of sale. About Us more than 400 own machines in stock over 12000 m² storage area, crane capacity 70 t more than 10000 articles accessories for your workshop You want to sell machines, production lines or your company, Then contact us.

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03735 · Lathe - cycle-controlled

MONFORTS - KNC 8 2000 - - - Monfort R&D

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03440 · Lathe - cycle-controlled

BOEHRINGER - DNE 820/DL 5000 - - - B2T

Technical details

- WMT GmbH & Co.KG

- Siemensstraße 1

- 46342 Velen-Ramsdorf

- Deutschland

-

+49 2863 92477-47

+49 2863 92477-50 -

info@w-m-t.de

www.w-m-t.de

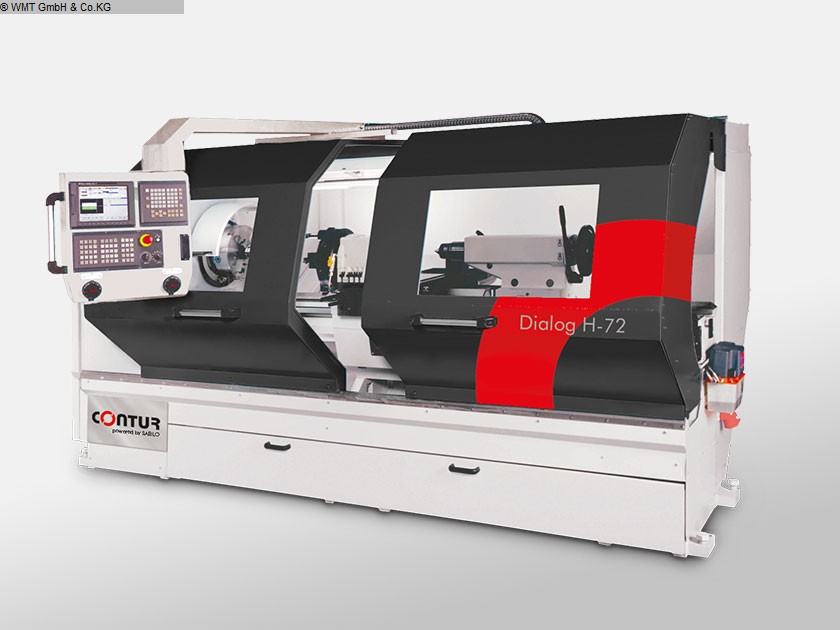

#1108-78103 · Lathe - cycle-controlled

SAEILO - CONTUR Dialog HS-71 - - - 840D SL + ShopTurn Siemens

Technical details

Lathe cycle controled VDF BOEHRINGER - DUS 560 / 3000

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-V0171 · Lathe - cycle-controlled

PADOVANI - Labor E 300 - - - Siemens 805

Technical details

3- jaw chuck diameter: 400 mm 4- jaw chuck diameter: 250 mm Fixed bezel diameter: 360 mmIncludes: 4 jaw turrets and coolant.

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-03704 · Lathe - cycle-controlled

MONFORTS - KNC5-1500 - - - Monforts MTCK

Technical details

The tech. Data are manufacturer or operator information and therefore for us not binding. We reserve the right to prior sale; it apply only our business and conditions of sale. About Us more than 400 own machines in stock over 12000 m² storage area, crane capacity 70 t more than 10000 articles accessories for your workshop You want to sell machines, production lines or your company, Then contact us.

- MS Maschinenhandel GmbH

- Unterdorf 34

- 6532 Ladis

- Österreich

-

+43 547221907

+43 54722190722 -

info@ms-maschinen.at

www.ms-maschinen.at

#2034-8360 · Lathe - cycle-controlled

CONTUR - DIALOG H-66 - - - SIEMENS 840 D + SHOPTURN

Technical details

- Valk Machines BV

- Kadijk 6

- 8531XD Lemmer

- Niederlande

-

+31 514562904

-

sales@valkmachines.com

www.valkmachines.com

#2079-066 · Lathe - cycle-controlled

Narvik - CD 460TI - - - Fagor 8055

Technical details

- HESSE+CO Maschinenfabrik GesmbH

- Straße 4 Objekt 8

- 2351 Wiener Neudorf

- Österreich

-

+43/2236/638 70-0

+43/2236/636 62 -

office@hesse-maschinen.com

https://www.hesse-maschinen.com

#1069-2118 · Lathe - cycle-controlled

ZMM - LS 600 M - - -

Technical details

Fast and simple communication between the operator and the lathe. Simple workpieces are machined in the same way as on the universal lathe, but more efficient. Complicated workpieces are machined in the same way as on the universal lathe, but faster. Complicated workpieces are machined in the same way as on the CNC lathe, but easier. Based on the controller Schneider Magelis the intelligent, self-developed ZMM Sliven software leads the operator also without programming skills simple and fast to the finished workpiece. The interface is simple and with large icons, which is convenient in a specific work environment. The intuitive menu facilitates the transition to next screens and operations. Well visualized and structured cyclic operations,threads and steps. Possibility to set up the feeds, threads, etc. both mechanically and digitally (via the display). The manual, automatic and combined mode allows more precise operation compared to universal lathe. Easy transition from manual to automatic operation mode. ACCESSORIES: Siemens motor with Siemens Inverter (3 gear steps) CNC control Schneider Magelis Quick change tool post Amestra Multifix Typ C inkl. 4 Halter (3x Rechteck, 1 Rund) 3-jaw chuck Bison 3204/DIN6350, Ø 250 mm, max. 2500 r/min Spindle dead center Ball screw spindles for longitudinal and cross axes Coolant equipment Full length rear splash guard Spindle protection Splash guard for the chuck Levelling bols and shims Quick release tailstock Machine lamp Operating manual Machine according to "CE“ FURTHER TURNING LENGTHS: 1000 mm € 67.640,00 2000 mm € 70.240,00 3000 mm € 72.940,00 4000 mm € 75.840,00 5000 mm € 78.640,00

Datasheet

Request / Contact

lathe-conventional-electronic

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6040 · lathe-conventional-electronic

MVE BAUART VDF - V 5 - 2000 - - unbekannt -

Technical details

Electric 380Volt 3-jaw chuck Forkardt F 315 Quick change steel holder with various inserts machine light Machine feet (6 pieces) Revolving tip Coolant system

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6622 · lathe-conventional-electronic

WEILER - Praktikant - - unbekannt -

Technical details

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06571 · lathe-conventional-electronic

VDF-BOEHRINGER - V5 - - unbekannt -

Technical details

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200006 · lathe-conventional-electronic

ZMM - C10T - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200003 · lathe-conventional-electronic

ZMM - CU325/1000 - - NEU -

Technical details

Furnishing: - Cooling device - Machine light - chip rear wall - Spindle protection - Lathe chuck protection - Tool holder protection - Foot pedal with braking function CE - Interchangeable gears *incl. Optional equipment - 3-jaw chuck Ø 160 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type A, incl. 4 tool holders - 2-axis digital display DRO Newall

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200001 · lathe-conventional-electronic

OPTIMUM - OPTIturn TH4215D - - NEU -

Technical details

Fully equipped master and feed spindle lathes. TH 4215 with digital position indicator DPA 21 / 3462070 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 6 - Precisely crafted slide - Hand wheels with adjustable fine scaling 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Adjustment range top slide ± 90° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Main spindle running in oil bath - Smooth-running gear wheels, hardened and ground with 2 adjustable Precision tapered roller bearings - Hand wheels decoupled and tested according to EN 23125 - Two-channel right-left switch tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - All metric pitches in the range 0.2 to 14mm/rev and all Inch threads in the range of 72 - 2 threads per inch without changing the Change gears adjustable by shift lever in the control panel - Clockwise/counterclockwise rotation can be switched on the bed slide via the switching spindle - Central lubrication in bed slide - Meehanite cast base and machine bed in one piece - Lead screw cover - Emergency stop device with foot control - Safety handwheels with snap-out function in the X and Z axes - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and hand wheel with adjustable fine scaling 0.025 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, induction hardened and precision ground cast iron - Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN - LED machine lamp in the chip guard Models TH 4210D and TH 4215D with digital readout DPA21 - User-friendly membrane keyboard, splash-proof, closed andglare-free - Glass scales scope of delivery - Fixed bezel passage Ø 15 - 145 mm - Revolving bezel passage Ø 10 - 75 mm - LED machine light - Reducing sleeve MT 6 / MT 4 - Fixed center MK 4 - Change gear set - Position stop with fine adjustment - Initial filling of the machine with quality oil - Operating tool ** Incl. special accessory OPTIMUM three-jaw lathe chuck centrically clamping Ø 250 mm ** Quick change holder SWH5-B set

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7375 · lathe-conventional-electronic

OPTIMUM - OPTIturn TH 3309D - - NEU -

Technical details

Fully equipped leading and tension spindle lathes. TH 3309D with digital position indicator DPA 21/3402040 - Hardened and ground Z-axis guideway - Spindle mount Camlock DIN ISO 702-2 No. 4 - Precisely crafted slide - Handwheels with adjustable fine scale 0.04 / 0.02 mm - Quadruple steel holder - All guides can be adjusted using V-ledges - Main spindle running in an oil bath - Gear wheels run smoothly, hardened and ground - Upper slide adjustment range ± 90 ° - Guaranteed concentricity of the spindle nose better than 0.015 mm - Handwheels decoupled and tested according to EN 23125 - Safety handwheels with push-out function in the X and Z axes - Two-channel right-left switch tested according to EN 23125 - DC 24 volt electrical system with two-channel safety circuit according to EN 23125 - Lathe chuck protection tested according to EN 23125 - Switch with life cycle calculation, tested according to EN ISO 13849 - Lockable main switch - Clockwise / counterclockwise rotation on the bed slide switchable - Lead screw cover - Tailstock for taper turning adjustable ± 10 mm - Tailstock quill and handwheel with adjustable fine scale 0.02 mm - Quick, easy and tool-free adjustment using a clamping lever - Heavily ribbed prism bed, inductively hardened and precision ground - Machine base with tool compartment on the right-hand side (left-hand side with 3 Bezels (no compartments) - Pull-out chip tray with guide rails - Emergency stop device with foot actuation - LED machine lamp integrated in the chip guard Digital position indicator DPA 21 - User-friendly membrane keyboard, splash-proof, closed and glare-free - glass rulers scope of delivery - Fixed steady rest passage Ø 6 - Ø 50 mm - Moving steady rest passage Ø 8 - Ø 30 mm - LED machine light - Reduction sleeve MK 5 / MK 3 - Two fixed centering points MK 3 - Quadruple steel holder 16 mm - Change gears set - machine base - Initial machine filling with quality oil - operating tool ** Including special accessories OPTIMUM three-jaw lathe chuck, centric clamping Ø 200 mm Camlock DIN ISO 702-2 No. 4/3442762

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200004 · lathe-conventional-electronic

ZMM - C10TM/3000 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200002 · lathe-conventional-electronic

ZMM - CU400/1500 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2200005 · lathe-conventional-electronic

ZMM - CU400/1000 - - NEU -

Technical details

- Coolant device - Machine light - Chip back wall - Spindle protection - Lathe chuck protection - Tool holder protection - Interchangeable gears *Special equipment - 3-jaw chuck Ø 250 mm type 3204/ DIN6350, BISON - MULTIFIX quick-change holder type B, including 4 tool holders - 3-axis digital display DRO Newall - Foot pedal with brake function CE

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-06443 · lathe-conventional-electronic

GILDEMEISTER - MF 65 - - 2x 1999 / 1x 2000 - 2x 840 D

Technical details

TOP Manufacturer:

WEILER - KRAFT - MONFORTS - GILDEMEISTER - PINACHO - SEIGER - SOMAB - BOEHRINGER - SAEILO - DMTG -