Suction

Machinelist: Suction

Cleaning unit

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7233 · Cleaning unit

DIBO - CT80 BT 70 - - 2020 -

Technical details

- Exhibition machine and demonstration machine, like new- - Most compact ride-on scrubber-dryer from DiBO with 2 brushes - Possibility to dispense detergent: in ECO mode with constant Saving or automatic regulation of the machine depending on the speed of the machine Brush motors and suction: even less energy consumption, even more Smoothness - Display: large, multilingual, including hour counter, battery level and work programs - Memory card: allows the storage of battery charge cycles and Power consumption of the motor - CFS system: water distribution from the middle of the brush to avoid waste Avoid cleaning solution - SLS system: self-leveling electronic system to keep the brush always lies perfectly on the floor - EDD system: suction cup for the best results during drying and during Area performance was developed - Wheels: oil resistant - Extraction: 2 levels with fans and stainless steel shaft

- G. FOLMER Industriebedarf

- Mangenbergerstr. 347

- 42655 Solingen

- Deutschland

-

+49 21241071

+49 21241276 -

folmer.maschinen@t-online.de

#2010-592 · Cleaning unit

Vorwerk - Flaechenwaescher - - 2019 -

Technical details

Datasheet

Request / Contact

- Aleman Machines e.K.

- Am Mühlweg 1

- 73466 Lauchheim

- Deutschland

-

+49 (0)7363-6098 20

+49 (0)7363-6098 19 -

info@aleman-machines.com

www.aleman-machines.com

#1120-975 · Cleaning unit

HEIN HESO - Compo 1020 WST - - 2016 -

Technical details

- IMZ Maschinen Vertriebs GmbH

- Marie-Curie-Straße 19

- 73529 Schwäbisch Gmünd

- Deutschland

-

0049 (0) 7171 987130

0049 (0) 7171 9871329 -

info@imz.de

www.imz.de

#1075-6585 · Cleaning unit

DEBUS - DES 119 - - 2013 -

Technical details

swarf cleaner

Datasheet

Request / Contact

- ATMH Werkzeugmaschinenhandel GmbH

- Scharpenbergerstr.96-98

- 58256 Ennepetal

- Deutschland

-

+49 (0) 2333 / 403 43 70

+49 (0) 2333 / 403 43 75 -

info@atmh.de

www.atmh.de

#2065-S592 · Cleaning unit

HAKO - HAKOMAT B70 CLHM - - 2013 -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-6754 · Cleaning unit

TENNANT - Tennant 7100 - - 2009 (2021) -

Technical details

Sweeper - scrubber dryer Operating hours: approx. 400 hours incl. 4x brush + charger including new battery pack (consisting of 6x gel battery) !!

- Marcels Maschinen AG

- Anthoptstrasse 11

- 8222 Beringen (Schaffhausen)

- Schweiz

-

(0041) 44 872 3400

(0041) 44 872 3403 -

info@marcels-maschinen.ch

http://www.marcels-maschinen.ch

#1065-4963 · Cleaning unit

JETO - EUROCLEAN - - 2000 -

Technical details

Datasheet

Request / Contact

- Zuefle GmbH

- Levi-Strauss-Str. 121

- 97232 Giebelstadt

- Deutschland

-

+49 (0)9334-978608-0

+49 (0)9334-978608-2 -

info@zuefle.com

www.zuefle.com

#1139-LS7007 · Cleaning unit

Kohlhoff Hygienetechnik Sailer - SSR-1 - - 09/2014 -

Technical details

APRON CLEANER APRON CLEANER for thorough cleaning and disinfection of aprons in meat processing plants. Application: the apron is held by the person cleaning it in a plastic funnel and sprayed with water in a targeted manner via movements using an integrated high-pressure pump with a capacity of 100 bar/water pressure, even heavily soiled aprons are reliably cleaned in max. 15 seconds, meat residues and fibres are rinsed out of the butcher's apron, the high-pressure water jet is activated via a foot switch, cleaning or disinfecting agent is automatically added to the water via a dosing system to optimise the cleaning result. cleaning agent or disinfectant to the water via a dosing system, collection container with sliding lid for easy access for cleaning and maintenance work, including canister holder for cleaning agent for lateral mounting on the side of the housing. Electrical connection: 400 V/N/PE, 50/60 Hz, power consumption: 5.6 kW Water connection: 3/4" max. 40°C, min. 2.5 bar, water drain DN50, water connection min. 20 l/min, When connecting the machine to the drinking water system, an approved pipe isolator must be provided on site. Dimensions: (W x D x H): 800/1053 x 750 x 950/1480 mm The unit can be inspected under power near Ulm. Arrange an appointment. for thorough cleaning and disinfection of aprons in meat processing plants. Application: the apron is held by the person cleaning it in a plastic funnel and sprayed with water in a targeted manner via movements using an integrated high-pressure pump with a capacity of 100 bar/water pressure, Even heavily soiled aprons are reliably cleaned in max. 15 seconds, meat residues and fibres are rinsed out of the butcher's apron, the high-pressure water jet is activated via a foot switch, cleaning or disinfecting agent is automatically added to the water via a dosing system to optimise the cleaning result. cleaning agent or disinfectant to the water via a dosing system, collecting tank with sliding lid for easy access for cleaning and maintenance work, including canister holder for cleaning agent for lateral mounting on the side of the housing. Electrical connection: 400 V/N/PE, 50/60 Hz, power consumption: 5.6 kW Water connection: 3/4" max. 65°C, min. 2.5 bar, water drain DN50, water connection min. 20 l/min, When connecting the machine to the drinking water system, an approved pipe isolator must be provided on site. Dimensions: (W x D x H): 800/1053 x 750 x 950/1480 mm The unit can be inspected under power near Ulm. Arrange an appointment.

Suction

- EMUK GmbH Werkzeugmaschinen

- Siemensstrasse 24 a

- 76316 Malsch

- Deutschland

-

+49 (0) 7246 1392

+49 (0) 7246 1394 -

info@emuk.de

www.emuk.de

#1058-24029 · Suction

INDUSTAR - 1N80A2 - - UNBEKANNT -

Technical details

Datasheet

Request / Contact

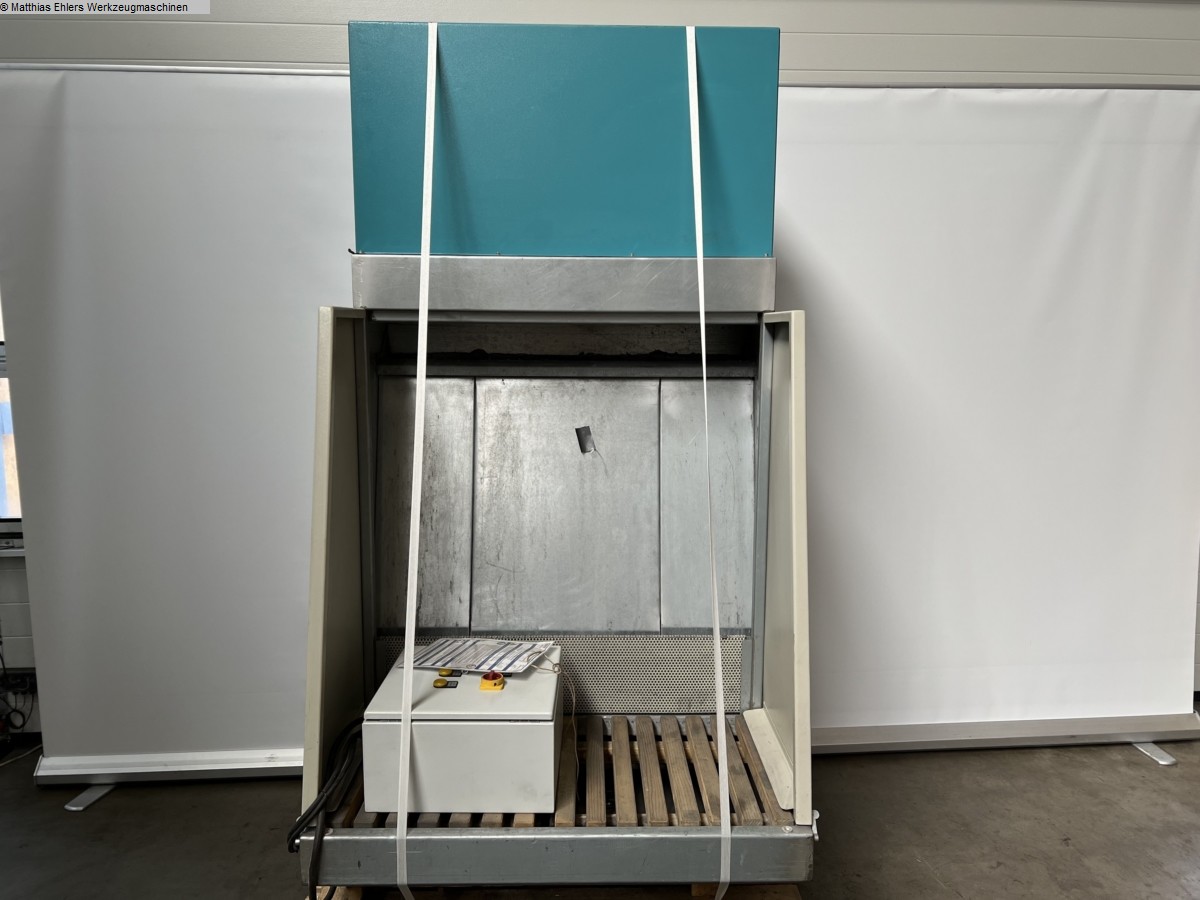

- Matthias Ehlers Werkzeugmaschinen

- Nikolaus-Otto-Straße 19 + 21

- 22946 Trittau

- Deutschland

-

+49 (0)4154 - 986 99 12

+49 (0)4154 - 986 99 14 -

anfrage@ehlers-wzm.de

www.ehlers-wzm.de

#2033-2023247 · Suction

TECHNO-JET - 4MD - - unbekannt -

Technical details

Datasheet

Request / Contact

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2810012 · Suction

TEKA - Cartmaster - - NEU -

Technical details

- Hose arm 3 m, joints inside - Filter cartridge: dust class M - Pre-filter: baffle plate - Current type: 3Ph+N+PE The filter system --------------------------------------- The mobile filter system of the Cartmaster IFA type is thanks to the automatic Cleaning particularly suitable for welding work with unalloyed and alloyed steels, galvanized material and aluminum with heavy smoke development. It corresponds to the safety requirements for devices Welding fume class "W3" (high-alloy steels with alloy components > 30% Nickel-based alloy).If used as intended, the system can be used for the Recirculation mode used because the requirements for the Exceptions according to TRGS 560 are fulfilled. That special developed, dirt-dependent cleaning system ensures a good cleaning behavior of the filter cartridge, so that an optimal suction performance is guaranteed throughout the operation. The cleaned particles fall into a dust collection drawer from which they can then be disposed of. The powerful spiral fan ensures even with saturated Filter cartridges for a high volume flow. The filter media --------------------------------------- A baffle serves as a pre-separator for coarse particles. The filter cartridge installed below (dust class M, degree of separation > 99%) filters the finest smoke and dust particles. The cartridge is factory coated which increases the service life. The extraction arm ------------------------ The extraction arm can be moved with the 3 internal joints Position spring support slightly and is in the set position cantilevered. A throttle flap integrated in the extraction hood enables the Flow rate setting.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-8366978 · Suction

TEKA - filtoo 1,1 kW 1x3 mtr. - - NEU -

Technical details

Particle pre-separator: coarse filter, pre-filter Main particle separator: main filter Gas separator: activated carbon filter Hose arm: joints inside What is the filtoo? The filtoo filter device newly developed by TEKA is a mobile filter system, for many tasks in the area of ??filtration of smoke and dust and gases can be used. The device was based on DIN EN ISO 15012-1 (2005) tested and is IFA (formerly BGIA) certified (IFA No. 201020469/1140) for welding smoke class "W3" (degree of separation:> 99.9%). at The filtoo is intended to be used for the separation of smoke suitable, which by welding separation and joining processes at the Machining of unalloyed steels, including high-alloy chrome / Nickel steels are released. How does the filtoo work? The Polluted air sucked into the filter system. In a multi-level The filter process filters the particles / gases from the air stream and the clean air is fed back into the work area. Where can the filtoo be used? At welding workplaces, in the workshop area, for soldering applications, at Restorers and locksmiths. What do you get for your money? All you get is a completely ready-to-use "plug and play system" the recording device must be connected before commissioning. How is the filtoo set up? The housing is made of a stable sheet steel construction and is inside as well as provided with a powder coating on the outside. The filter elements are over A maintenance hatch is accessible and can therefore be accessed very easily and quickly can be removed. The system has functional controls.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-7227 · Suction

NOVUS - Airtower FT 20.000 - - NEU -

Technical details

Modular plug & play airtower for hall extraction of welding fumes with integrated, soundproofed Fan, automatic, differential pressure controlled Filter cleaning, system control with color display, particle pre-separation and IFA - tested filter cartridges. The system is for a volume flow of average 20,000 m³ / h designed 1st filter stage - main filter: Filter area: 222 m² Number of filters: 6 pieces Dust class according to DIN EN 60335-2-69: M. Degree of separation:> 99.9% Cleaning: Jet - Pulse Compressed air connection: NW 7.2 mm, 4-6 bar, oil and water free 2nd filter stage - fine dust filter. Filter area: 65 m² Filter class according to ISO 16890: ISO ePM1 80% 3rd filter stage - Synthetic fiber mats: Filter area: 8 m² Filter class according to ISO 16890: ISO coarse 60% Total filter area: 295 m² Dimensions: Width filter unit: 2,066 mm Depth filter unit: 1,756 mm Height of filter unit: 3,643 mm Dust container: 200 liters Version Sanders incl .: - NOVUS efficiency package FT20.000 - timer - NOVUS particle sensor

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-2810013 · Suction

TEKA - StrongMaster IFA - - NEU -

Technical details

mobile extraction, welding fume extraction (manual cleaning by loss of pressure) - Hose arm 3 m, joints inside - Filter cartridge: dust class M - Particle pre-separator: baffle plate - Current type: 3Ph+N+PE The filter system --------------------------------------- The mobile filter system of the type StrongMaster IFA is particularly suitable for Welding work with unalloyed and alloyed steels, galvanized material and Aluminum in case of heavy smoke development. She corresponds to the Safety requirements for devices in the welding fume class "W3" (high-alloy steels with alloy components > 30% nickel-based alloy). When used as intended, the system can be used for be used in the recirculation mode, since the requirements for the Exceptions according to TRGS 560 are fulfilled. The filter will via a maintenance door using a compressed air gun from the clean air side cleaned. The cleaned particles fall into a dust collection drawer from the they can then be disposed of. The powerful scroll fan ensures a high volume flow even with saturated filter cartridges. The filter media --------------------------------------- A baffle serves as a pre-separator for coarse particles. The filter cartridge installed below (dust class M, degree of separation > 99%) filters the finest smoke and dust particles. The cartridge is factory coated which increases the service life. The extraction arm ------------------------ The extraction arm can be moved with the 3 internal joints Position spring support slightly and is in the set position cantilevered. A throttle flap integrated in the extraction hood enables the Flow rate setting.

- Matthias Ehlers Werkzeugmaschinen

- Nikolaus-Otto-Straße 19 + 21

- 22946 Trittau

- Deutschland

-

+49 (0)4154 - 986 99 12

+49 (0)4154 - 986 99 14 -

anfrage@ehlers-wzm.de

www.ehlers-wzm.de

#2033-2023081 · Suction

HEAB - HAL-1 / BEAL - 100/50 - - 2018 -

Technical details

In our opinion, the machine is in very good condition and can be viewed by appointment. ***Accessories, tools and clamping devices shown are only part of the scope of delivery if this is noted in the additional information.*** *** Changes and errors in the specifications and information, as well Subject to prior sale! ***

Datasheet

Request / Contact

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-Z01052 · Suction

TEKA - 792SAD - - 2011 -

Technical details

Sweat extractionThe techn. Data are manufacturer or operator information and therefore non-binding. We reserve the right to prior sale; Our terms and conditions of sale apply exclusively.About usMore than 400 of our own machines in the warehouseMore than 12,000 m² of storage space, crane capacity 70 tMore than 1000 items Accessories for your workshopYou want to sell machines, production lines or your company,then contact us.

- Heinz Sanders GmbH

- Fresenburger Weg 4

- 49779 Niederlangen

- Deutschland

-

+49 (0) 5939 9406 40

+49 (0) 5939 9406 50 -

maschinen@heinz-sanders.de

www.heinz-sanders.de

#1125-3810005 · Suction

TEKA - WNA 7500 A - - 2011 -

Technical details

- Markus Hirsch GmbH

- Hüttenstrasse 1

- 46284 Dorsten

- Deutschland

-

+49 2362 95035 12

+49 2362 95035 10 -

liersch@hirsch-maschinen.de

www.hirsch-maschinen.de

#1077-Z01062 · Suction

Donaldson - Tovit DCE Top 450 - - 2003 -

Technical details

Sweat extractionThe techn. Data are manufacturer or operator information and therefore non-binding. We reserve the right to prior sale; Our terms and conditions of sale apply exclusively.About usMore than 400 of our own machines in the warehouseMore than 12,000 m² of storage space, crane capacity 70 tMore than 1000 items Accessories for your workshopYou want to sell machines, production lines or your company,then contact us.

- Christoph Busch GmbH

- Dieselstr. 22

- 41352 Korschenbroich

- Deutschland

-

+49 (0) 2182 570 5930

+49 (0) 2182 5785202 -

mail@busch-gruppe.de

www.busch-gruppe.de

#2052-05980 · Suction

KEMPER - System 5000 - - 2000 -

Technical details

++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++ Please note: The machine is dismantled and ready for loading. It is not possible to show it under power or make a video. Our offer includes already the best pictures. So we don’t have and won’t send additional pictures. ++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++++

- Hans Klein Werkzeugmaschinenhandel GmbH

- Im Mühlgut 2-4

- 77815 Bühl

- Deutschland

-

0049 (0) 7223 9617-0

0049 (0) 7223 58512 -

info@klein-werkzeugmaschinen.de

www.klein-werkzeugmaschinen.de

#1052-11010 · Suction

VENTI OELDE - 162 - - 1992 -

Technical details

Datasheet

Request / Contact

- Kurt Steiger Werkzeugmaschinen GmbH

- Flachstr. 11

- 65197 Wiesbaden

- Deutschland

-

+49 (0) 611/421047

+49 (0) 611/421040 -

info@kurt-steiger.de

www.kurt-steiger.de

#2043-27011b · Suction

KEMPER - 91550 - - 1991 -

Technical details

extraction capacity: 1200 m³ / h

drive: 0.75 kW

space requirement: 700 x 660 x 1030 mm

Nugbwpet

Datasheet

Request / Contact

- Kurt Steiger Werkzeugmaschinen GmbH

- Flachstr. 11

- 65197 Wiesbaden

- Deutschland

-

+49 (0) 611/421047

+49 (0) 611/421040 -

info@kurt-steiger.de

www.kurt-steiger.de

#2043-27011a · Suction

KEMPER - 91550 - - 1991 -

Technical details

Extraction capacity: 1200 m³ / h

Bjljxyczux

Drive: 0.75 kW

Space requirement: 700 x 660 x 1030 mm

Datasheet

Request / Contact

- Sachsenring Werkzeug Maschinen GmbH

- Talstr. 77 B

- 09337 Hohenstein-Ernstthal

- Deutschland

-

+49 (0)3723 / 6684755

+49 (0)3723 / 6684750 -

info@swmgmbh.de

swmgmbh.de

#2038-500104 · Suction

Opitz - Sto 5/125 - - 1969 -

Technical details

Extraction, Type: Sto 5/125, Manufacturer: WMW, Year of manufacture: 1969,

Datasheet

Request / Contact

- Kurt Steiger Werkzeugmaschinen GmbH

- Flachstr. 11

- 65197 Wiesbaden

- Deutschland

-

+49 (0) 611/421047

+49 (0) 611/421040 -

info@kurt-steiger.de

www.kurt-steiger.de

#2043-26858a · Suction

unbekannt - - - -

Technical details

Inlet diameter: 55 mm

1 suction speed

Becnc3xw7x

Electr. Connection: 230 V

Space: 700 x 280 x 370 mm

Datasheet

Request / Contact

- 1

- 2

TOP Manufacturer:

TEKA - KEMPER - LINCOLN ELECTRONIC - ALKO - VENTI OELDE - HEAB - UNBEKANNT - OPITZ - INDUSTAR - ELEKTROSTATIK/MESSER GRIESHEIM -