FLECKENSTEIN Werkzeugmaschinen GmbH - Stockist for used machines

Machinelist:

Drilling and Milling M/C

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1622 · Drilling and Milling M/C

Castel - GREEN 1T4 - - 1997 -

Technical details

Equipment. • CNC-control HEIDENHAIN 430 • support bearing • manual milling head • coolant tank with pump

Datasheet

Request / Contact

Table Type Boring and Milling Machine

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-16220 · Table Type Boring and Milling Machine

Castel - GREEN 1T4 - - 1997 - HEIDENHAIN TNC 430

Technical details

Equipment. • CNC-control HEIDENHAIN 430 • support bearing • manual milling head • coolant tank with pump

Datasheet

Request / Contact

Bed Type Milling Machine - Universal

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

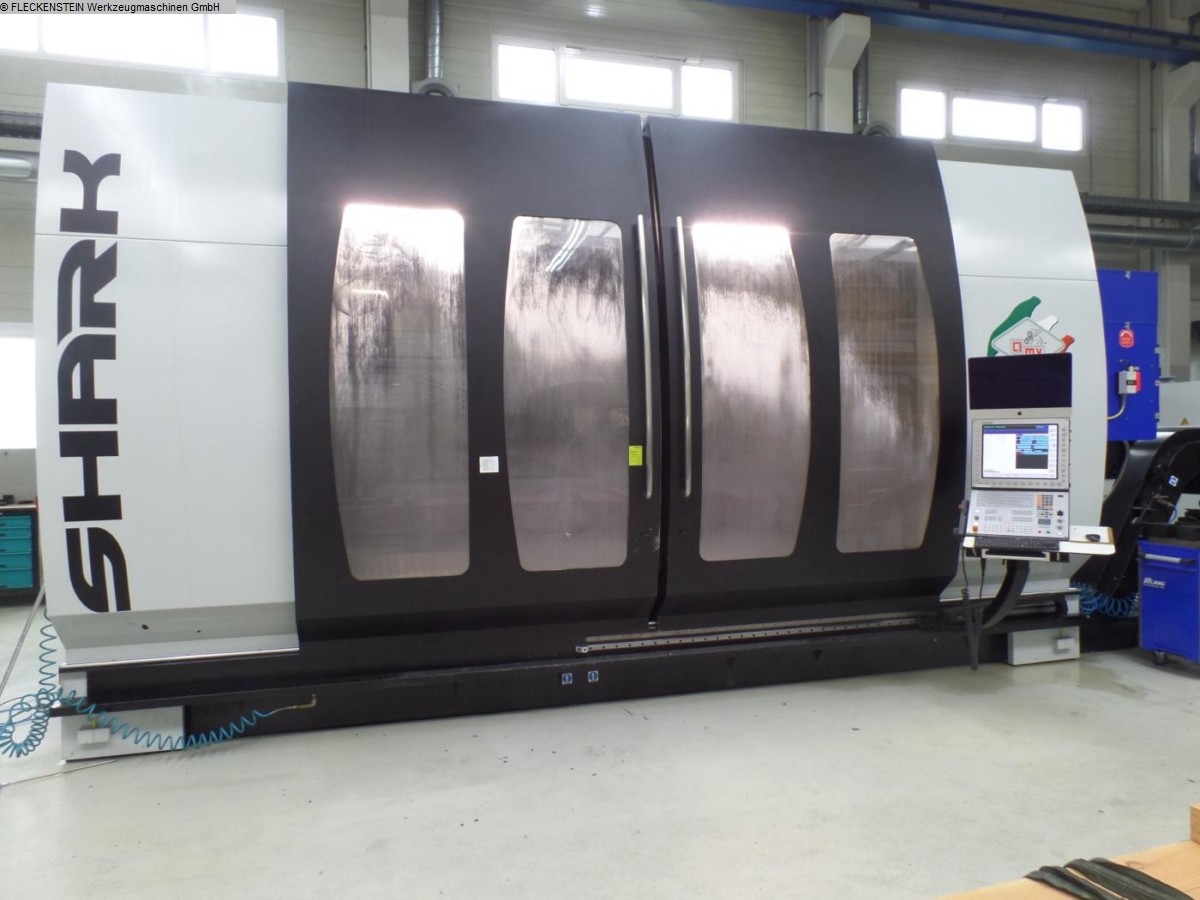

#1118-1592 · Bed Type Milling Machine - Universal

PARPAS - SHARK One - - 2016 - HEIDENHAIN iTNC 530 HSCI

Technical details

Equipment • Machine bed, column and vertical saddle as welded steel construction, annealed with low tension • Milling slider as welded steel construction • Orthogonal milling head TUB-E92 with motor spindle, C- and A-axis drive via torque motors • Oil cooling unit for cooling the milling head • CNC thermal compensation • Spindle drive 29 kW • Spindle speed max. 18.000 min-1 • Axle drives by means of precision ball screws and digital servo motors • Touch probe system manufacturer BLUM, TC 63-30 with radio transmission and automatic measuring cycles • Milling head Measurement “Kinematics Opt” • Laser tool presetter BLUM - NT version mounted on machine table • CNC control HEIDENHAIN iTNC 530 HSCI incl. digital drive technology • Portable electronic handwheel HEIDENHAIN HR 520 with 3 m spiral cable • swivelling control panel for machine operation in front of the machine • Automatic tool changer with 30 magazine places, change position vertical • Coolant system with external shower rim and IKZ through the spindle • 1 chip conveyor in the working area, ejection right • Pretensioned linear guides in all axes • Precision ball screws in Y- and Z-axis • X-axis drive via gear rack and master/slave drive • Hydraulic weight compensation in the vertical axis • Bellows cover of the X-axis • Milling slide above and below in the vertical axis with bellows covers with attached stainless steel lamellas closed • Work area enclosure closed on all sides. Back side of the work area with bellows cover with attached stainless steel lamellas closed. The manual sliding doors on the front of the machine can be opened and closed over the entire length of the table. Safety fencing for the back machine area with two secured access doors.

Datasheet

Request / Contact

Double Column Milling M/C - Gantry Type

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1620 · Double Column Milling M/C - Gantry Type

TRIMILL - VF3016 - - 2017 - HEIDENHAIN iTNC530 HSCI

Technical details

Equipment / Accessories • 5-axis vertical portal milling machine in Gantry design. • Fork milling head T21C for simultaneous milling operation with FISCHER spindle, 42kW, 67Nm, 24.000 rpm, HSK-A63 • Manually operated textile roof • Tool changer chain 50-fold, change orientation vertical • 3D probe for workpiece measurement • Process monitoring system MONTRONIX incl. installed vibration sensors for detection of abnormal vibrations during the machining process. Alarm triggering, feed rate reduction or machine stop are carried out via the control system • HEIDENHAIN HR550 handwheel (wireless) • BLUM LaserControl NT for non-contact tool measurement with automatic cover, enables increased process reliability through automatic form and wear control of the tools used • Coolant system KNOLL for cooling lubrication with supply via spray nozzles and supply through the main spindle (ICS) • TRIMILL Kinematics - application for rotary axes • TRIMILL Teleservice - remote support • Linear, absolute and direct path measuring systems make HEIDENHAIN in X, Y and Z axis with a resolution of 0,001mm • Hydraulic power unit • 1 lubrication unit for the machine • 1 lubrication unit for the milling spindle • 1 cooling unit for cooling the milling head • 1 cooling unit for cooling the axis motors • 1 pc. Air extraction unit for oil and cooling lubricant emulsion with three-stage filtering, power consumption 2.2 kW, max. extraction capacity 2,000 m³. Extraction capacity 2.000 m³/h • 2 scraper belt conveyors, positioned along the X-axis to the left and right of the machine table, discharge height approx. 1,050mm program hours on the machine: approx. 8.000h

Datasheet

Request / Contact

Travelling column milling machine

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

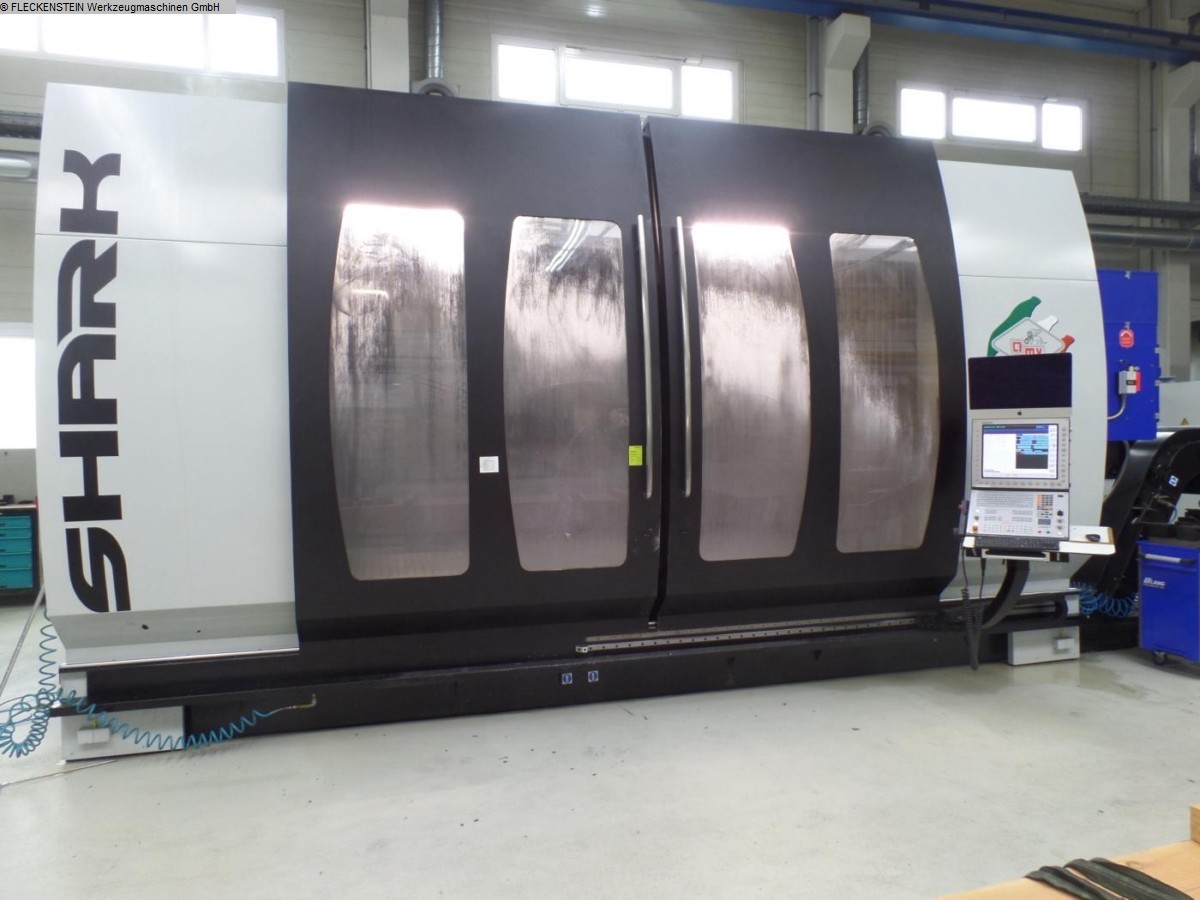

#1118-15921 · Travelling column milling machine

PARPAS - SHARK One - - 2016 - HEIDENHAIN iTNC 530 HSCI

Technical details

GEquipment • Machine bed, column and vertical saddle as welded steel construction, annealed with low tension • Milling slider as welded steel construction • Orthogonal milling head TUB-E92 with motor spindle, C- and A-axis drive via torque motors • Oil cooling unit for cooling the milling head • CNC thermal compensation • Spindle drive 29 kW • Spindle speed max. 18.000 min-1 • Axle drives by means of precision ball screws and digital servo motors • Touch probe system manufacturer BLUM, TC 63-30 with radio transmission and automatic measuring cycles • Milling head Measurement “Kinematics Opt” • Laser tool presetter BLUM - NT version mounted on machine table • CNC control HEIDENHAIN iTNC 530 HSCI incl. digital drive technology • Portable electronic handwheel HEIDENHAIN HR 520 with 3 m spiral cable • swivelling control panel for machine operation in front of the machine • Automatic tool changer with 30 magazine places, change position vertical • Coolant system with external shower rim and IKZ through the spindle • 1 chip conveyor in the working area, ejection right • Pretensioned linear guides in all axes • Precision ball screws in Y- and Z-axis • X-axis drive via gear rack and master/slave drive • Hydraulic weight compensation in the vertical axis • Bellows cover of the X-axis • Milling slide above and below in the vertical axis with bellows covers with attached stainless steel lamellas closed • Work area enclosure closed on all sides. Back side of the work area with bellows cover with attached stainless steel lamellas closed. The manual sliding doors on the front of the machine can be opened and closed over the entire length of the table. Safety fencing for the back machine area with two secured access doors.

Datasheet

Request / Contact

Gear Shaping Machine

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1554 · Gear Shaping Machine

LORENZ - LS 82 - - 1999 - SIEMENS 840 C

Technical details

equipment · stroke positioning adjustment controlled by CNC · stroke length adjustment mechanical-manually · machine is fixed to the ground with specific damping shoes (part of the delivery scope) · oil mist exhaust system · tailstock · shaping spindle and lift of shaping head equipped with hydrostatic bearing

Datasheet

Request / Contact

Cylindrical Grinding Machine - Universal

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1628 · Cylindrical Grinding Machine - Universal

DANOBAT - R3-4000-S5 - - 2001-2023 -

Technical details

Equipment & Accessories CNC cylindrical grinding machine in most robust design for heavy workpieces • Scope of geometric retrofit: • Slideways of X- and Z-axis regrinded, intermediate table and top table regrinded • Centre height of headstock and tailstock readjusted • Machine checked from the bottom up and rebuilt • Cabling in the machine renewed • Hydraulic tubes and lines renewed • Ball screws of X- and Z-axis renewed • New bellows • Wearing parts replaced • New machine painting in two-layer-structure with oil-resistant and abrasion-resistant two-component paints, color RAL 7035 light gray and RAL 5007 brilliant blue • CNC Control SINUMERIK 840 D • New balancing of the grinding wheel • 2 pc. Grinding wheels Ø 1.000 x 60 x 304,8 mm • 2 pc. Support bearing • Front drivers + 1 pc. travelling tailstock tip • Coolant unit with belt filter • Full enclosure of the workspace with 2 large sliding doors • Extraction unit for emulsion mist

Datasheet

Request / Contact

Optical Profile Grinding Machine

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-15990 · Optical Profile Grinding Machine

ABA - Powerline - - 2001-2023 - SINUMERK 840 D

Technical details

Equipment and accessories - Linear measuring systems in Y- and Z-axis - All linear axes with digital servo motors and ball screw drive - Belt filter system with paper belt filter, tank capacity 640 l, coolant pump 200 l/min/4 bar - Manual coolant nozzles - adjustable - Automatic working chamber door pneumatically controlled - Electro-permanent magnetic plate 800 x 500 mm, pendulum pole pitch 18 mm - Automatic grinding wheel balancing device Fa. MPM - Full enclosure of the working area in stainless steel partial execution with LED working area lighting - Manually operated door, safety interlock in automatic mode - Portable electronic handwheel in automatic and manual mode for all axes - Three-color signal light - Electrical equipment 400V/50Hz - Switch cabinet cooling unit - Machine feet - Painting RAL 9002 (grey white), RAL 5010 (gentian blue) - Rinsing gun with hose and holder in the operating area - Approx. 5 pcs. grinding wheel flanges *** Machine prepared for grinding mist suction *** Grinding programs - Surface grinding - Plunge grinding - Profile grinding - Automatic program sequence with roughing, finishing, fine finishing and burnout - Multiple plunge-cut grinding for economical production - Surface grinding with continuous, infinitely programmable cross feed - Calibration of the grinding wheel (calibrate, backfeed, round corners) - Face grinding with back pull dressing - Dressing in grinding cycle with lift-off amount - Fully automatic compensation of dressing amounts - Tool management Dressing Technology Table dresser -straight- TAG: Dresser fixed on the machine table, roughing and finishing station with dressing tiles are arranged one behind the other, cylindrical dressing of grinding wheels for surface and plunge grinding, suitable for corundum and silicon carbide grinding wheels, cycle software with input menu Pre-profiler VPG-150: incl. diamond roughing wheel width 1.5 mm For economical pre-profiling (roughing out) of the grinding wheel, profiling unit firmly mounted on the table, suitable for corundum and silicon carbide grinding wheels, CNC dressing cycle for pre-profiling Table profile dresser TAD: Suitable for diamond wheel DFR, D = 120, tip radius r = 0.1 - 1mm, flank angle 28°,40°, 60°. Profile depth max. 20 mm, contour accuracy +/- 0.0025 mm, swivel angle +/- 70°, profiling in the program by means of graphical operator guidance in 3-D interpolation

Datasheet

Request / Contact

Surface Grinding Machine - Horizontal

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-1599 · Surface Grinding Machine - Horizontal

ABA - Powerline - - 2001-2023 - SINUMERK 840 D

Technical details

Equipment and accessories - Linear measuring systems in Y- and Z-axis - All linear axes with digital servo motors and ball screw drive - Belt filter system with paper belt filter, tank capacity 640 l, coolant pump 200 l/min/4 bar - Manual coolant nozzles - adjustable - Automatic working chamber door pneumatically controlled - Electro-permanent magnetic plate 800 x 500 mm, pendulum pole pitch 18 mm - Automatic grinding wheel balancing device Fa. MPM - Full enclosure of the working area in stainless steel partial execution with LED working area lighting - Manually operated door, safety interlock in automatic mode - Portable electronic handwheel in automatic and manual mode for all axes - Three-color signal light - Electrical equipment 400V/50Hz - Switch cabinet cooling unit - Machine feet - Painting RAL 9002 (grey white), RAL 5010 (gentian blue) - Rinsing gun with hose and holder in the operating area - Approx. 5 pcs. grinding wheel flanges *** Machine prepared for grinding mist suction *** Grinding programs - Surface grinding - Plunge grinding - Profile grinding - Automatic program sequence with roughing, finishing, fine finishing and burnout - Multiple plunge-cut grinding for economical production - Surface grinding with continuous, infinitely programmable cross feed - Calibration of the grinding wheel (calibrate, backfeed, round corners) - Face grinding with back pull dressing - Dressing in grinding cycle with lift-off amount - Fully automatic compensation of dressing amounts - Tool management Dressing Technology Table dresser -straight- TAG: Dresser fixed on the machine table, roughing and finishing station with dressing tiles are arranged one behind the other, cylindrical dressing of grinding wheels for surface and plunge grinding, suitable for corundum and silicon carbide grinding wheels, cycle software with input menu Pre-profiler VPG-150: incl. diamond roughing wheel width 1.5 mm For economical pre-profiling (roughing out) of the grinding wheel, profiling unit firmly mounted on the table, suitable for corundum and silicon carbide grinding wheels, CNC dressing cycle for pre-profiling Table profile dresser TAD: Suitable for diamond wheel DFR, D = 120, tip radius r = 0.1 - 1mm, flank angle 28°,40°, 60°. Profile depth max. 20 mm, contour accuracy +/- 0.0025 mm, swivel angle +/- 70°, profiling in the program by means of graphical operator guidance in 3-D interpolation

Datasheet

Request / Contact

Built-In Rotary Table

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-Z1215 · Built-In Rotary Table

FIBRO - FIBROPLAN - - unbekannt -

Technical details

NC rotary table make FIBRO type FIBROPLAN Ø 800 mm rotary table with increased geometric accuracy with 8 star-shaped T-slots 18H8 according to DIN650 with centering hole Ø40H6 mounting height 250mm total ratio 1:600 direct measuring system ROD880C/36000 weight approx. 950 kg

Datasheet

Request / Contact

Clamping Chuck

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-Z1204 · Clamping Chuck

FORKARDT - 3WF 400 K15 S23 - - unbekannt -

Technical details

1 piece 3-jaw power chuck make FORKARDT type 3WF 400 K15 S23 Ø 400 mm with centrifugal force compensation

Datasheet

Request / Contact

Cutters

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-9889 · Cutters

GLEASON PHOENIX - WEDG-AC - - fast neu -

Technical details

GLEASON WEDG - AC 30 211 006 F7 4655 0003 366

Datasheet

Request / Contact

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-9888 · Cutters

GLEASON - HARDAC II - - fast neu -

Technical details

Type Nr.30212024, F-Nr.F746550002933, Anz. Messer 20, Anz. d. Messerköpfe a. Lager 9 Type Nr.30212025, F-Nr.F746550002934, Anz. Messer 20, Anz. d. Messerköpfe a. Lager 18 Type Nr.30212026, F-Nr.F746550002935, Anz. Messer 20, Anz. d. Messerköpfe a. Lager 25 Type Nr.30212027, F-Nr.F746550002936, Anz. Messer 20, Anz. d. Messerköpfe a. Lager 1 Type Nr.30212006, F-Nr.F746550002939, Anz. Messer 12, Anz. d. Messerköpfe a. Lager 19 Type Nr.30233008, F-Nr.F746550299197, Anz. Messer 22, Anz. d. Messerköpfe a. Lager 2 Alle Werkeuge 9 Zoll

Datasheet

Request / Contact

Vise

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-Z1211 · Vise

SINUS - - - unbekannt -

Technical details

1 pc. used SINUS vice "094372" jaw width 64 mm jaw height 30 mm max. clamping length 80 mm total height approx. 110 mm base plate 175 x 95 mm

Datasheet

Request / Contact

- FLECKENSTEIN Werkzeugmaschinen GmbH

- Sommerweg 15

- 63831 Wiesen

- Deutschland

-

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20 -

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

#1118-Z1212 · Vise

SINUS - - - unbekannt -

Technical details

1 pc. used SINUS vice "088972 jaw width 65 mm jaw height 30 mm max. clamping length 80 mm total height approx. 92 mm base plate 220 x 130 mm

Datasheet

Request / Contact

Fleckenstein Werkzeugmaschinen GmbH

Sommerweg 15

Contact Trader

Fleckenstein Werkzeugmaschinen GmbH

Sommerweg 15

63831 - Wiesen

Deutschland

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

Contact person:

Wir sind ein international tätiges Handelsunternehmen für gebrauchte Werkzeugmaschinen und Produktionsanlagen und bereits seit 30 Jahren am Markt etabliert. In unseren Lagern finden Sie ausschließlich hochwertige Maschinen und Produktionsanlagen namenhafter Hersteller. Durch den Ankauf und der Lagerung auf ca. 2.400 m2 kann ein Großteil der Anlagen unter Strom besichtigt werden.

Nutzen Sie unseren erweiterten Service, Demontage, Montage und Inbetriebnahme bis hin zur produktionsfertigen Übergabe.

Sommerweg 15

63831 - Wiesen

Deutschland

+49 (0) 6096 9706 0

+49 (0) 6096 9706 20

fleckenstein@fleckenstein-machine.com

www.fleckenstein-machine.com

Contact person:

Wir sind ein international tätiges Handelsunternehmen für gebrauchte Werkzeugmaschinen und Produktionsanlagen und bereits seit 30 Jahren am Markt etabliert. In unseren Lagern finden Sie ausschließlich hochwertige Maschinen und Produktionsanlagen namenhafter Hersteller. Durch den Ankauf und der Lagerung auf ca. 2.400 m2 kann ein Großteil der Anlagen unter Strom besichtigt werden.

Nutzen Sie unseren erweiterten Service, Demontage, Montage und Inbetriebnahme bis hin zur produktionsfertigen Übergabe.

Machine category

Bettfräsmaschine - Universal · Bohr- und Fräsmaschine · Einbaurundtisch · Fahrständerfräsmaschine · Flachschleifmaschine - Horizontal · Messerköpfe · Portalfräsmaschine verfahrbar · Profilschleifmaschine · Rundschleifmaschine - Universal · Schraubstock · Spannfutter · Tischbohrwerk · Zahnradstossmaschine ·