Kemmerich Werkzeugmaschinen GmbH - Stockist for used machines

Machinelist:

Bar Automatic Lathe - Multi Spindle

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20255 · Bar Automatic Lathe - Multi Spindle

TORNOS - MultiSwiss 8x26 - - 2018 - Fanuc

Technical details

CNC multi-spindle automatic lathe - Fanuc CNC Control TB-Deco - Oil cooling - All axes fully CNC - 1 x counter spindle - 4 x rear end machining - Belt conveyor for finished parts - 2x 80 bar high pressure pumps - Kraft & Bauer fire extinguishing system - Hinged belt conveyor - Bar loader - Paper belt filter - Including all existing processing units and accessories Running time 8,070 hours

Center Lathe

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19541 · Center Lathe

LEINEN - DLZ 140 - - 197 -

Technical details

- Forkhardt 3-jaw Chuck F 160 - Chuck guard - Lamp - Tailstock MK 3 - change gears - div tool holders, steels, tailstock tips - collet chuck

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19914 · Center Lathe

WOHLENBERG - W 50 x 6000 - - 1962/2015 -

Technical details

Overhauled in 2015 and since then only sporadically in use - Faceplate - chuck guard - 2 steady rests - Tailstock

CNC Lathe

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19803 · CNC Lathe

DMG GILDEMEISTER - CTX ALPHA 500 - - 2011 - SIEMENS 840 D

Technical details

4 axes CNC lathe - CNC control Siemens 840D solutionline with CELOS and ShopTurn 3G - main & counter spindle - C- & Y-axis (+/- 40 mm) - 12-axis turret with driven tools (VDI 30) - Hainbuch chuck - chip conveyor with 6 motorized tools and a lot of tooling 37800h running hours and 19800 spindle hours

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20287 · CNC Lathe

BOLEY - BE 42 - - 2005 - Mitsubishi Meldas 635

Technical details

- CNC control Mitsubishi Meldas 635LCC - Collet holder for main spindle - Pick-up spindle - Collet chuck holder for pick-up spindle - Pick-up spindle indexing - 2 12-position turrets with driven tools (VDI 20) - Warning light (3 colors) - Coolant tank - Spindle cooling unit - Central lubrication - Door interlock - Chip conveyor - Parts conveyor belt - Bar loader LNS Quick Load Servo III

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20274 · CNC Lathe

MAZAK - Quick-Turn 100 SG - - 12/2021 - Mazatrol Smooth C

Technical details

- CNC control Mazatrol Smooth C - Tool turret 12-position - center Tooleye - Tailstock MT4

CNC Lathe - Inclined Bed Type

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19147 · CNC Lathe - Inclined Bed Type

SPINNER - PD 400 C/S CNC - - 2004/2022 - Fanuc 18 iTB

Technical details

2022 New glass scale Heidenhain and replacement of smaller parts, new FANUC CNC Keyboard CNC - Ultra precision turning centre (X-, Z-, E-, C-Axe) - CNC control Fanuc 18iTB - Main and counter spindle - SAUTER tool turret 16-fold (0.5.480.510) VDI 16 - Linear tool slide - automatic doors - Chip tray - Coolant system with fine filter (high Pressure Pump) - 3 jaw chucks - Various clamping devices/pressure collets - Various tool holders Control On: 24000h

CNC Turning- and Milling Center

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20232 · CNC Turning- and Milling Center

DMG MORI - CLX 750 V4 - - 2021 - Sinumerik 840 D SL

Technical details

equipped with: - CNC control Siemens 840D MultiTouch - C-axis, y-axis - 12-position tool turret VDI 50(4000 rpm, 12,5 kW) - Chip conveyor with coolant system - Hydr. 3-jaw chuck SMW BH-D 400/A2-11 - Hydr. tailstock - Suction unit approx. 710h Machine On Hours and 175 Spindle Hours

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20063 · CNC Turning- and Milling Center

DMG MORI - CTX beta 1250 TC - - 2014 - Siemens 840D

Technical details

CNC - Turning and milling center - 5 axes - CNC control Siemens 840D Ergo Line with ShopTurn - C-axis (0,0001°) - Milling head with B-axis - Y-axis - Coolant device/paper belt filter - chip conveyor - Tool changer 24-fold (HSK A63) - Direct measuring system - IKZ 25bar - Tailstock

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20313 · CNC Turning- and Milling Center

MAZAK - Integrex i-100S - - 2013 - Mazatrol Matrix 2

Technical details

5-axis simultaneous machining - CNC control Mazatrol Matrix 2 - Main & counter spindle - 6" chuck (B206) - Tool changer (36-fold) HSK - Coolant system - Chip tray

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20092 · CNC Turning- and Milling Center

DOOSAN - Puma MX 2500 LST - - 2008 - FANUC 18i TB

Technical details

- CNC control FANUC Series 18i TB - Milling Head (Capto C6) - lower Tool Revolver 12-fold, driven tools 5,5kW - ATC for 40 tools - main and sub spindle with C-Axis each - Chip Conveyor - Coolant with paperband filter ca 12.000h "Run Time"

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20290 · CNC Turning- and Milling Center

SMEC - SL 2500 LY (B) - - 12/2020 - Siemens 828D

Technical details

equipped with: - CNC control Siemens 828D with Manual Guide I - 12-position tool turret (BMT65) -- driven tools 5000 rpm, 5,5/8,3kW -- 2 rotating axial tool holders -- 2 radial rotating tool holders - Bar loader interface - coolant system 10bar - tool measuring probe - Tailstock (MT 5) - Chip conveyor Power On: 4519h Cutting Time: 860h

Facing Lathe

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-19718 · Facing Lathe

POREBA - TZG 250 A - - 1992 -

Technical details

- Digital Read Out - Chip Conveyor - Hydr. Copy Attachment

Hardturning & Grinding Center

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-18522 · Hardturning & Grinding Center

BUDERUS - CNC 235 DH-I-T-SL - - 2012 - Siemens Sinumerik 840D

Technical details

The CNC 235 vertical hard machining center with vertical workpiece spindle allows the use as single-purpose machine for - Internal grinding - External grinding - Hard Turning Furthermore, these processes can be combined with each other and be supplemented by other technologies. equipped with: - CNC Control Siemens 840D - 2 Toolrevolver (li/re) Size 16 - 2 spindle units (X1, C1, Z1 / X2, C2, Z2) - Marposs Workpiece- & Tool Control E9066N - Dittel AE 6000 - GMN High Frequency Spindle HVX 12 2 identic units available

Heavy Duty Lathe

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

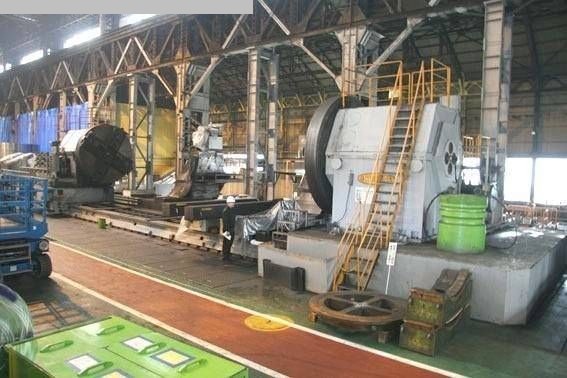

#1020-15807 · Heavy Duty Lathe

FRORIEP - SS 60 x 13000 - - ca. 1975 -

Technical details

Heavy Duty Lathe with 4-guides bed and is equipped with 2 cross-slides: - one is mounted on a chassis bed installed next to the main chassis of the lathe - one is mounted on an upper chassis bed on top of the main chassis of the lathe - the upper chassis bed is also movable on top of the main chassis of the lathe Max length of workpiece on main chassis: 13 meter Max length of workpiece on top of upper chassis bed: 6,5 meter Max swing in gap using main cross-slide: 4000 mm Max swing over bed using using secondary cross-slide: 2700 mm Max swing over cross-slide: 2220 mm - 8 Steadies

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20235 · Heavy Duty Lathe

TOSHIBA - LCS 40200A CNC - - 1976 /2009 - Fanuc 18i TB

Technical details

overhauled and modernized in 2008/2009, equipped with: - CNC control FANUC 18i TB - face plate - 2 slides with control unit - 2 heavy duty steady rests (200t support load each), dia: 600-2000mm - Hydrostatic bearing in spindle & tailstock - 5 lanes bed - chip conveyor - Coolant system - Tailstock with faceplate (dia. 3000mm)

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-18487 · Heavy Duty Lathe

ZERBST - DxP5/W15x15000 - - 1959/2009 - Siemens 840 Dsl

Technical details

overhauled and modernized 2009 & 2012/2013 equipped with: - CNC control Siemens 840D SL ShopTurn - 2 supports with 1 controller each - 4-jaw face plate - 2 hydraulic steady rests (1760mm) - hydraulic tailstock Machine is dismantled and stored.

Lathe - cycle-controlled

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20337 · Lathe - cycle-controlled

SEIGER - SLZ 500E - 1000 - - 2019 - Siemens 840D

Technical details

- Control unit Siemens 840D - 3-jaw chuck - Support with 2 tool holders ( - steady rest - Tailstock ( air pressure supported ) - chip conveyor - Coolant system * only 5720h operating hours * very good condition

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-17734 · Lathe - cycle-controlled

POREBA - TBA 63 x 2000 - - 2004 - Fanuc PowerMate

Technical details

Cycle Controlled Lathe with: CNC control Fanuc PowerMate/QuickTurn - 1 Steady 370mm - 1 steady 160mm - 1 Röhm chuck 400mm - Chip Tray with Coolant Pump - Tool Holder, Accessories

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-15885 · Lathe - cycle-controlled

WEILER - E 70 /2x2000 - - 1997/2018 - Siemens Sinumerik 805

Technical details

2018 Check of the Main Gear Box and change of parts like Bearing, Gears etc CNC control Siemens Sinumerik 805 - 1 Steady 400mm - 1 chuck 400mm - Coolant Tank

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-18395 · Lathe - cycle-controlled

BOEHRINGER - DUS 560 x 1250 - - 1995 - Sinumerik 805 Siemens

Technical details

Lathe cycle controled - SIEMENS Sinumerik 805 / Simeodrive 611 - 4-Jaw Chuck, Handwheel, Covering - Chip Tray & coolant - adjustable feet - approx 20 tool holders 2021 Electrics/controls check by Boehringer

Turning Automatic Lathe - swiss lathe

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20253 · Turning Automatic Lathe - swiss lathe

TRAUB - TNL 32 -7B - - 2019 - Traub System TX 8i-s

Technical details

- Control system TX 8i-s - Oil cooling - Kraft & Bauer fire extinguishing system - Two turrets (all tools powered) - B-axis (upper turret) - Rear processing (stationary tools) - 1 x counter spindle - Picking pliers for finished parts - Belt conveyor for finished parts - High pressure pump - Hinged belt conveyor - Paper band filter - FMB Turbo 3-36 bar feeder - Including all existing processing units and accessories Running time according to the control 19,616 hours Running time according to the control 11,630 hours automatic Manual counter running time 17,972 hours

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20256 · Turning Automatic Lathe - swiss lathe

TORNOS - Swiss DT 13 - - 2016 - Fanuc 31i-B

Technical details

CNC sliding headstock automatic lathe - Fanuc 31i-B control - Oil cooling - Kraft & Bauer fire extinguishing system - All axes fully CNC - 3 x driven tools - 1 x counter spindle - 4 x driven tools for back machining - Chute for finished parts - 60 bar high pressure pump - Hinged belt conveyor - Tornos Robostar SBF 213 bar feeder Including all existing machining units and accessories Running time 15,476 hours

- Kemmerich Werkzeugmaschinen

- Im Rottfeld 1a

- 40789 Monheim am Rhein

- Deutschland

-

+49 2173 207474

+49 2173 207473 -

info@kemmerich.biz

www.kemmerich.biz

#1020-20254 · Turning Automatic Lathe - swiss lathe

TRAUB - TNL 18P - - 2011 - Traub System TX 8i-p

Technical details

- TX 8i-p control unit - Oil cooling - Kraft & Bauer fire extinguishing system - Motor spindle max. passage LW 20mm - max. 10,000 rpm - Stroke max. 205 mm (long rotation version) - Stroke max. 80 mm (short turning version) - Two turrets (8 WZ top 10,000 rpm, 7 WH bottom 10,000 rpm) - Rear machining (7 turrets, 3 of which 10,000 rpm) - Counter spindle Ø 20mm max. 12,000 rpm - KSS pump 30 bar - Finished parts are rinsed out - Belt conveyor for finished parts - Hinged belt conveyor - Paper belt filter - FMB Turbo 3-36 bar feeder - Including all existing processing units and accessories Running time according to control system 53,636 hours On Running time according to control unit 35,940 hours automatic Running time manual counter 48,808 hours

Профиль трейдера: Kemmerich Werkzeugmaschinen

Ltd.

Связаться с торговцем

Ltd.

В красном поле 1a

40789 - Монхайм-на-Рейне

Германия

+ 49 2173 207474 "> + 49 2173 207474

+49 2173 207473

info@kemmerich.biz

www.kemmerich.biz

Профиль пользователя Trader

| ||||||||||||

| ||||||||||||

| Г-н Фолькер Кеммерих | Г-н Андреас Кеммерих |

| Телефон: 02173 / 207472 | Телефон: 02173 / 207474 |

| Факс: 02173 / 207473 | Факс: 02173 / 207473 |

| E-Mail: sales@kemmerich.biz | E-Mail: info@kemmerich.biz |

Im Rottfeld 1a

Contact Trader

Im Rottfeld 1a

40789 - Monheim am Rhein

Deutschland

+49 2173 207474

+49 2173 207473

info@kemmerich.biz

www.kemmerich.biz

Contact person:

Herrn Andreas Kemmerich +49 2173 207474

Seit 1982 ist die Firma Kemmerich Werkzeugmaschinen GmbH auf dem sich ständig ändernden Werkzeugmaschinen-Markt aktiv und handelt als international tätiges Maschinen-Handelsunternehmen mit gebrauchten Maschinen für die spanabhebende und spanlose Verarbeitung der metallverarbeitenden Industrie

Kemmerich ist dabei auf Zahnradbearbeitungsmaschinen und Maschinen der Schwerzerspanung, wie zum Beispiel Dreh-, Fräs- und Schleifmaschinen sowie Bohrwerke, spezialisiert. Die Maschinen kommen unter anderem in der Automobilindustrie (Ausrüster und Zulieferer), im Zahnrad- und Getriebebau, der Produktion von Kugel- oder Wälzlagern, dem allgemeinen Maschinenbau zum Einsatz.

Ansässig ist das Unternehmen inzwischen in Monheim am Rhein, im Herzen des Rheinlandes und in unmittelbarer Nähe zu den Messestädten Köln und Düsseldorf und deren Flughäfen. Dort stehen auf einer 2.200 qm großen, beheizbaren Ausstellungsfläche eine Vielzahl von konventionellen wie auch CNC/SPS-gesteuerten Metall be- und verarbeitenden Werkzeugmaschinen stets zur Besichtigung und Vorführung bereit.

Mit einer Krankapazität von 32 Tonnen können jegliche Art von Maschinen gehändelt und bewegt werden. In der eigenen Werkstatt werden die Funktionsfähigkeit der Maschinen überprüft und gegebenenfalls festgestellte Mängel beseitigt. Zudem werden Maschinen auf Kundenwunsch modernisiert und modifiziert. Das Leistungsspektrum des Unternehmens umfasst zudem die Demontage oder Demontageüberwachung, Verladung, Verpackung sowie Land-, Seetransport und Zollabwicklungen, Montage und Inbetriebnahme beim Kunden durch Vermittlung von Spezialisten, Präsentation der Maschinen unter Strom (soweit möglich), Durchführung von Maschinenbewertungen und die Vermittlung von Kontakten.

Anstatt in neue, teure Werkzeugmaschinen zu investieren und um lange Lieferzeiten zu umgehen, lohnt es sich oftmals, eine gut gepflegte Gebrauchtmaschine zu kaufen.