Knops Werkzeugmaschinen GmbH & Co. KG - Stockist for used machines

Machinelist:

Center Lathe

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2333 · Center Lathe

WOHLENBERG-LÖW - V 1000 - - 1990 -

Technical details

* D.R.O. * Steady-rest * 3-jaw-chuck, diameter 310 mm, with several jaws * Toolholder with several inserts

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2300 · Center Lathe

VDF BOEHRINGER - DUE 500 - - 1989 -

Technical details

* 2-axes D.R.O. * 3-jaw-chuck FORKARDT F250 * Faceplate * Rapid traverse * Multifix toolholder * 2 x steady-rest * Coolant equipment * Documentation

Datasheet

Request / Contact

CNC Turning- and Milling Center

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2331 · CNC Turning- and Milling Center

HWACHEON - HI-TECH 200BL MC - - 2014 - FANUC 0i-TD

Technical details

Very good condition, little used ! Machine comes from a factory closure. * CNC control FANUC 0i-TD * C axis * 12-pos turret with powered positions (3,7/2,2 kW, 5000 rpm) * Internal cooling at 17 bar * Tailstock * Collet chuck up to 60 mm diameter * 3-jaw chuck, diameter 250 mm * 2 driven tool holders for machining the lateral surface * 2 driven tool holders for machining the end face

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2323 · CNC Turning- and Milling Center

GILDEMEISTER - CTX Beta 800 - - 2012 - Siemens 840 D

Technical details

CNC turning and milling center in good condition with driven tools, C and Y axis, subspindle and CNC control Siemens 840 D. Operating hours according to the attached photo from February 8, 2024 The hours may increase as the machine is currently still in use. Max. workpiece diameter 410 mm Max. workpiece length 800 mm Max. travel X-axis 300 mm Max. travel Y-axis +/- 50 mm Max. travel Z-axis 850 mm Turning diameter over cross slide 250 mm Main spindle drive power 65 kW Spindle bore 75 mm Spindle speed of the main spindle 4000 rpm. Spindle speed of the counter spindle 5000 rpm. Equipment and accessories: Chip conveyor Coolant system with paper belt filter Oil mist extraction system Electrical control cabinet with air conditioning (tropical package) 3-jaw power chuck on main and subspindle Basic equipment of tool holders Documentation/Manual

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E06177 · CNC Turning- and Milling Center

CITIZEN BOLEY - Evoluturn BE 42 - - 2005 - MITSUBISHI

Technical details

CNC lathe in very good condition. Operating hours according to the mechanical counter only 10549 hours!!! The machine can be demonstrated under power. Video: https://www.youtube.com/watch?v=S2992uq4WnQ&t=1s Equipment: CNC control MITSUBISHI C axis Driven tools Two disc turret Main and counter spindle Bar loader make LNS, model QUICK Load Servo 3, year of construction 2005 Bar length approx. 1500 mm Chip conveyor Huge accessory package with tool holders, tools, collets, etc.

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2284 · CNC Turning- and Milling Center

GILDEMEISTER - GMX 300 linear - - 2004 - SIEMENS 840 D

Technical details

First put into operation February 2005 Working hours February 2024: - Machine on: 64.333 h - Program-cycle: 41.420 h - Spindle-hours: 32.272 h * Main and subspindle, 2 x C-axis * 3-jaw power chuck RÖHM KFD-HS 250/3 for mainspindle * 3-jaw power chuck RÖHM KFD-HS 250/3 for subspindle * CNC control SIEMENS Sinumerik 840 D powerline * Turning and milling unit (HSK-A63), B-axis, Y-axis * 120-station tool changer * 12-position turret (bottom), all positions driven (10.7 kW, 4000 rpm) * Cooling unit * Coolant filter system 980 L * Chip conveyor * Oilmist extractor Optionally, a short bar loader, make Breuning ILS, passage 90 mm can be offered for € 5.500,-

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2288 · CNC Turning- and Milling Center

GILDEMEISTER - TWIN 42 - - 2002 - Siemens 840 D Powerline

Technical details

Equipment: CNC control Siemens 840 D Powerline. 2 x 12-station turret, all positions driven (speed 30-6000 rpm., 3,8/2,1 kW) Y axis Collection device with gripper Belt filter system Bar feeder, make Breuning/IRCO, model ILS TBL 72.12, bar length 1200 mm Counter spindle from RUN-TEC, completely overhauled Additional tailstock under the counter spindle Chip conveyor

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08710 · CNC Turning- and Milling Center

MAZAK - Integrex 200 SY + GL100C - - 2001 - MAZATROL 640 MT

Technical details

MAZATROL 640 MT control max. turning diameter 540 mm Z-axis movements 1.065 mm Main spindle, max. speed 5.000 rpm Main spindle full C-axis Sub spindle, max. speed 6.000 rpm Y-axis +/- 80 mm Milling spindle, max. speed 6.000 rpm Full B-axis, 225° ATC 40 tools KM-63 toolholders Tooleye 1 x 3-Backenfutter, Diameter 210 mm 1 x 3-Backenfutter, Diameter 170 mm Portallader Flex GL-100C High pressure coolant, 20 bar Swarf conveyor

Datasheet

Request / Contact

Facing and Centering Lathe

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E05430 · Facing and Centering Lathe

WMW ZERBST - DP 4000 ... DP 5000 - - retrofit 2014 -

Technical details

Facing and Centering Lathe with plate field - Max. Turning diameter over the bed slide 4000 mm - Max. Turning diameter 5000 mm - Max. Turning length: 22000 mm - Face plate speed range 0.9 - 56 rpm - Faceplate diameter 4420 mm - Main motor 30 kw - Torque on the faceplate 61803 Nm - Max. Workpiece weight between the centers: 20 t - Max. workpiece weight -without tailstock: 12,5 t - Two bed slides with 4500 mm turning length - With plate fields - A roller block - With tailstock Machine was overhauled in Italy in 2014 with stepless speed control. After the overhaul, the lathe was no longer operational. Machine is dismantled and stored near Hamburg.

Datasheet

Request / Contact

Heavy Duty Lathe

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08290 · Heavy Duty Lathe

QIQIHAR - HT125x110/12 - - 2009 -

Technical details

Center height 720 mm Center distance 11000 mm Turning diameter over bed 1250 mm Turning diameter over slide 1000 mm Workpiece weight max 12 to Speed 3-315 rpm - stepless Motor power 55 kW (DC) Equipment 1 position indicator HEIDENHAIN | Type ND 780 for 1 axis 1 four-jaw faceplate Ø 1000 mm 1 fixed steady rest 1 ring steady rest with four-jaw faceplate Ø 920 mm 1 Autom. 4-pos. tool holder 1 Chip conveyor 1 Machine lamp 1 Coolant device Operating key | operating manual

Datasheet

Request / Contact

Deephole Boring Machine

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08962 · Deephole Boring Machine

BUCK - TBFZ 2000 CNC - - 1998 - Heidenhain TNC 430

Technical details

CNC deep drilling and milling machine BUCK TBFZ 2000 CNC suitable for deep hole drilling and milling of cubic workpieces. Technical data Travel paths: X - axis (longitudinal) 2000 mm Y - axis (vertical) 1000 mm Z - axis (drilling axis/drilling depth) 1500 mm W axis (boom) 500 mm B-axis (rotary table) 0-360° Drilling/milling unit: Tool holder SK 50 according to DIN 69871 Speed 0-6000 rpm Drive power 17.25 kW at 60% ED NC rotary table (B axis): Clamping table 1800 x 1500 mm Table load max. 20000 kg Feed speed: X-axis (machine column) 0-15000 mm/min Y-axis (vertical slide) 0-15000 mm/min Z axis (drilling slide) 0-15000 mm/min Work performance in material 1.2312: Drilling diameter with ELHB 4 - 32 mm Thread cutting M30, larger threads by milling Milling capacity 250 cc High pressure coolant system: Tank size approx. 2000 liters Pump performance infinitely adjustable - Min. delivery rate 16 l/min at 70 bar - Max. delivery rate 48 l/min at 18 bar - Drive power 15 kW CNC Control: Heidenhain TNC 430 CNC with electronic handwheel ARTIS tool breakage monitoring General data: Operating voltage 380 V / 50 HZ Control voltage 24 V DC Total connected load approx. 40 kW Machine weight approx. 15.5 tons Space required approx. according to installation plan Machine equipment: - 20-pos tool changer on the pick-up system - 2 support steady rests for deep hole drilling - Scraper belt chip conveyor - Electronic handwheel - Flushing pump for external coolant supply - Machine enclosure according to CE - incl. accessory package (holder, drill bushings etc.)

Datasheet

Request / Contact

Machining Center - Horizontal

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2317 · Machining Center - Horizontal

STARRAG-HECKERT - HEC 400 Focus - - 2016 - Siemens 840 D sl

Technical details

* CNC-control SIEMENS Sinumerik 840 D sl * 80-pos. ATC * 2-pos. pallet changer * NC-rotary table * Increased spindle torque up to 259 Nm * Coolant equipment with paper band filter * Coolant through spindle 80 bar * Swarf conveyor Max. workpiece diameter: 750 mm

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E05884 · Machining Center - Horizontal

MCM - ACTION 2600 FFS - - 2008 - Fanuc 16 MB

Technical details

The system requires a space of approx. 42 x 18 m It is designed for "fully automatic operation" in 3 shifts. Components with tolerances of <0.01 mm were produced on the system. Equipment: CNC control Fanuc 16 MB 20-pos pallet changer Pallet size 1250 x 1000 mm Interference circle diameter up to 2700 mm Vertical tool magazine with 599 places HSK-A100 from 3 modules on 4 levels Rotary table (B-axis) with 3,600,000 angular positions Table load 4000 kg Spindle speeds 8,000 rpm. Motor power 26/37 kW Torque 605/707 Nm Chip disposal through two jet pipes in the existing central Chip disposal system Connection to an in-house central coolant system. IKZ spindle with supply of coolant through the center of the tool Cooling unit for working spindle use Electrical control cabinet with air conditioning Protective cover for the work area Protective fence cladding, sheet metal below and safety glass above, for the entire working area of ??the machine. Buffer shelf with 5 tool spaces for quick tool provision Tool cone cleaning High pressure coolant supply 65 bar Laser control of tool availability Inductive button for temperature compensation on the electrospindle Tool Monitor Renishaw button type RMP 60 Rotoclear AR aspirator Machine preparation for hydraulic clamping (on the turntable) Automation of the plant

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2306 · Machining Center - Horizontal

MAZAK - FH-8800 - - 2004 - Mazatrol PC Fusion 640 M

Technical details

New price over € 1,0 million. Equipment and technical data: CNC control Mazak Mazatrol PC Fusion 640 M With Performance CNC package EIA / ISO conversion Preparation measuring device for Renishaw Tool length measurement up to 600 mm Spindle speed max. 7000 rpm. Torque increased with 2 gear stages Tool holder BT/SK 50 Max. torque 1177 Nm With 10-pos pallet pool, can be reduced to 6 pallets B axis 360 x 1 deg Pallet size 800 x 800 mm Max. workpiece weight 2200 kg Max. workpiece diameter 1250 mm Max. workpiece height 1250 mm 240-fold tool changer (modified to 50% higher speed) Max. tool length 652 mm Max. tool diameter 135 mm, with free additional space 260 mm Tool weight 30 kg

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E06043 · Machining Center - Horizontal

MAZAK - FH 6800 - - 1999-09 - Mazatrol 640M

Technical details

Equipment Coolant through spindle Coolent system Chip conveyer Several tool holders Measuring probe Clampings Transport dimensions: Width: 2,60 m Hight: 3,20 m Length: 6,40 m

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-E06044 · Machining Center - Horizontal

MAZAK - FH 880 - - 1997-11 - Mazatrol

Technical details

Machine with coolant through spindle Transport dimensions: Width: 5.92 meters Height: 3.27 meters Length 4.21 meters

Datasheet

Request / Contact

Machining Center - Universal

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08361 · Machining Center - Universal

QUASER - MF 630C - - 2015 - Siemens 828 D

Technical details

ONLY 2800 HOURS SPINDLE WORKS Description The QUASER MF vertical machining centres are highly versatile, offering high speed, high powered machining with 4+1 and full 5-axis machining capability along with large X-axis machines with a compact footprint. Superb build quality and stability for high volume production, toolroom and subcontract machining environments. Specification Table size 500mm diameter Travels – X/Y/Z axes 800 x 700 x 610 mm A Axis + 30 deg ~ -120 deg C Axis 360 deg continous Maximum swing 630 mm Table surface to spindle nose -25mm ~ 585mm Spindle nose to tilting centre at 90 deg -25mm ~ 585mm Maximum work piece of size 630mm dia x 300mm Table load capacity 300kg Spindle taper BT40 Spindle options 10,000 / 12,000 / 15,000rpm ATC – Standard 30 Station ATC – Option 48 / 60 Station Machine weight 8750kg Features: Multi-face machining centre Siemens 828 D CNC Control 630mm maximum swing dia x 300mm high 40 Taper spindle Spindle oil chiller or ECO Chiller 30 station ATC (Options available) Coolant wash gun Coolant wash down Chip augers Cutter air blast Worklight Machine status light

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2274 · Machining Center - Universal

AXA - VHC 2-XTS/50 - - 2006 - Siemens 840 D

Technical details

Universal machining center for 5-axis simultaneous machining. Technical specifications: Traverse X/Y/Z 2360 x 600 x 800 mm Pendulum stroke with vertical spindle left/right 1160/700 mm Table clamping area 2750 x 600 mm with 4 T-slots Tool holder SK 50 Spindle speeds 30 - 4000 rpm. Equipment: CNC control Siemens 840 D with Shop Mill DIN ISO CNC rotary table type RTA 3-520 CNC swivel milling head infinitely variable positioning Tool changer with 26 tool places Chip conveyor Coolant system with high-pressure pump and belt filter system Coolant through spindle 20 bar Electric hand wheel Space requirements: Machine length 5650 mm + 1800 mm with chip conveyor Machine width 3500 mm plus control panel Machine height 3200 mm Machine without clamping vices and tool/holders.

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

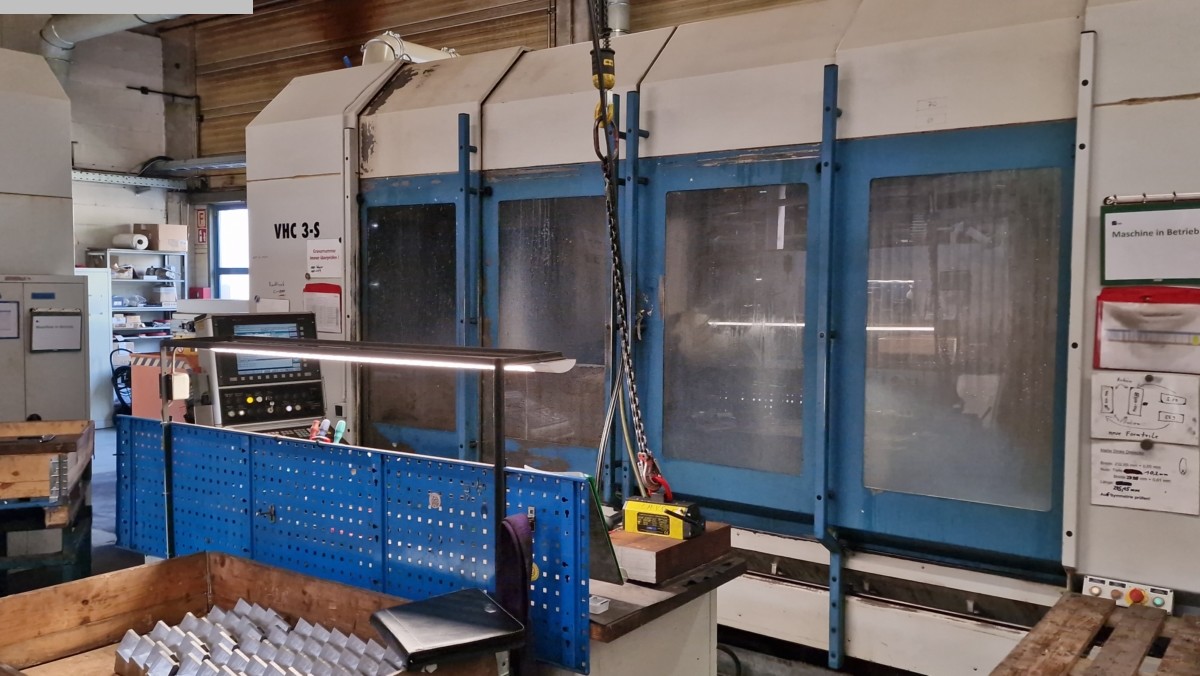

#1022-2273 · Machining Center - Universal

AXA - VHC-3-3000-S/50/E - - 2005 - Siemens 840 D

Technical details

Universal machining center for 5-axis simultaneous machining. Technical specifications: Traverse X/Y/Z 2940 x 700 x 850 mm Table size 3400 x 750 mm Pendulum stroke with vertical spindle left/right 1170/1170 mm Spindle speeds 30 - 6000 rpm. AC hollow shaft motor, power 45 kW at 40% ED Max. torque 286 Nm at 40% ED Tool holder SK 50 Equipment: CNC control Siemens 840 D with ShopMill CNC swivel milling head infinitely variable positioning directly programmable from X (-) 90° to X (+) 90° Locking via Hirth toothing Tapping without compensating chuck CNC rotary table, table diameter 630 mm Measuring system Heidenhain, direct linear Tool changer with 26 tool places Chip conveyor Coolant system with high-pressure pump and belt filter system Coolant through spindle 20 bar Space requirements: Machine length 5800 mm + 1700 mm with chip conveyor Machine width 3300 mm plus control panel Machine height 3200 mm

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08936 · Machining Center - Universal

MAZAK - VARIAXIS 730-5X - - 08-2004 - Mazatrol 640 M 5X

Technical details

The machine can be inspected in Bavaria, near the city of Bayreuth under power. CNC control Mazatrol 640 M 5X Table size: Ø 630 mm x 500 mm Travels: X: 730 mm Y: 850 mm Z: 560 mm A: +-30° to -120 C: 360° Distance table top to spindle nose: 230 to 790 mm Max. workpiece dimensions: Ø 1000 mm x 340 mm Load capacity of the table: 500 kg Spindle motor AC 44,4/30/22 kW Max. spindle speed: 10000 rpm tool holder SK 50 Tool magazine with 80 tool places Max. tool diameter: 125 mm / 210 mm Max. Tool length: 400 mm Cooling through the spindle High pressure pump 70 bar Mayfran Consep 2000 chip conveyor with drum filter

Datasheet

Request / Contact

Machining Center - Vertical

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08879 · Machining Center - Vertical

MAZAK - NEXUS 510-C-II - - 2007 - Matrix

Technical details

Switch-on time: approx. 23,000 hours The machine got new guides in the X and Y axes two years ago. About a year ago, the milling spindle, spindle motor and spindle controller renewed. CNC control Mazatrol Matrix traverse paths: X: 1050mm Y: 510mm Z: 510mm Rapid traverse X/Y/Z 36 m/min Distance table surface to spindle nose 150 - 660 mm Spindle motor 18.5 kW max. spindle speed 12000 rpm Tool magazine with 30 tool places SK-40, DIN 9871 Max. tool weight 8 kg Max. tool diameter 80/125 mm Max. tool length 350 mm Cooling through the spindle tool length measuring system chip conveyor Standard coolant pump Dimensions 2,973 x 2,835 x 2,845 mm Weight 6,900 kg CE mark

Datasheet

Request / Contact

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-H08880 · Machining Center - Vertical

MAZAK - NEXUS 410A-II - - 2006 - Matrix

Technical details

Mazatrol Matrix control Travel size: X axis: 560 mm Y axis: 410mm Z axis: 510mm Table size: 900 x 410 mm Max. table load 500 kg Milling spindle motor AC18.5/15/11/7.5 kW Max. spindle speed 12000 rpm SK-40, DIN69871 Tool magazine with 30 tool places Max. tool diameter 80 mm Max. tool length 350 mm Max. tool weight 8 kg tool length measurement Cooling through the spindle Mazak Monitoring B, incl. Renishaw OMP60 probe chip conveyor CE mark

Datasheet

Request / Contact

Portal - Machining Center

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

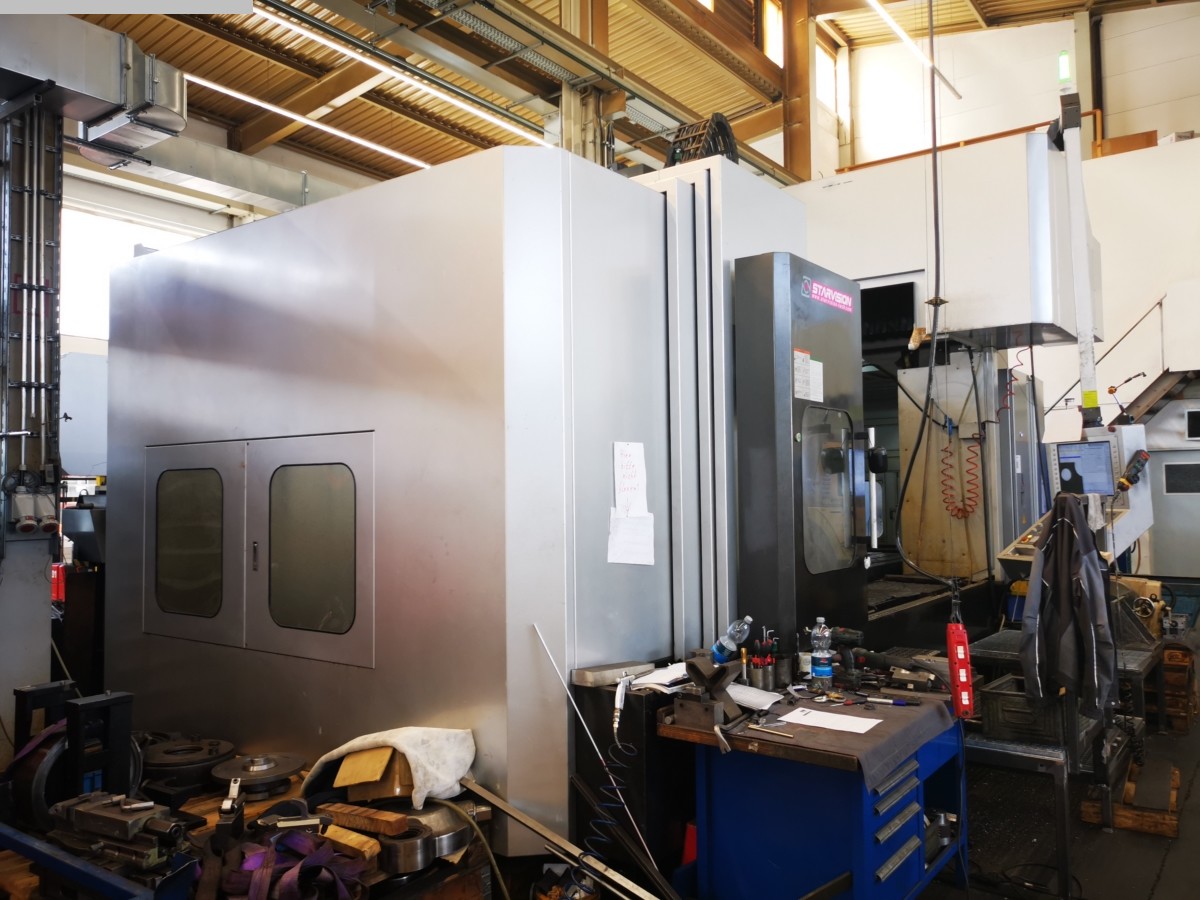

#1022-E06241 · Portal - Machining Center

Starvision - - - 2019 - Heidenhain iTNC 640

Technical details

Technical data: Travel paths Longitudinal travel / X-axis 3200 mm Cross travel / Y-axis 3400 mm Vertical travel / Z-axis 1200 mm Table clamping area 3000 x 2400 mm T-slots 13 x 28 x 180 mm Max. table load 11000 kg Spindle Motor power S1/S6-60%/S6-25% 32/43/53 kW Max. torque S1/S6-60%/S6-25% 819/1100/1356 Nm Spindle holder BTT 50-BIG PLUS Max. spindle speed continuously 6000 1/min. 2-stage gear drive / HAMADI KOKI - Japan Distance spindle nose - milling table 350 - 1550 mm Distance between stands 2800 mm Feeds Max. working feed 7000 mm/min. Rapid traverse X/Y 12000 / Z 15000 mm/min. General information Installation area with chip conveyor 10833 x 6680 mm Height 5702mm Net weight of the machine with accessories 40000 kg Standard equipment: CNC path control Heidenhain iTNC 640 Linear scales from Heidenhain in all X, Y and Z axes Axis motors from Heidenhain Spindle motor from Heidenhain Electronic handwheel from Heidenhain HR-510 Machine in a stable cast design Linear guides from Schneeberger, size 55 in the X axis, size 65 in the Z/Y axis Spindle oil cooler Coolant tank Complete coolant system Chip flushing pump Synchronized tapping/spindle orientation High precision ball screws grade C3 Double arm gripper tool changer 60 times Air blast to clean the spindle cone when changing tools Hydraulic tool clamping system Hydraulic weight compensation in the Z axis - double cylinder Automatic central lubrication Electric cabinet with air conditioning Full machine cladding with two sliding doors for easy machine access Twin screw chip conveyor (longitudinal) and hinged belt (transverse) Low voltage machine light and work status light RS 232 C, USB, Ethernet communication system and TELESERVICE Installation elements CE safety standards Including the following special accessories/options: Spindle motor from Heidenhain QAN 320 M (instead of QAN 260 UH) IKZ cooling through the spindle 20 bar with Grundfos high-performance pump with microfilter Air cooling through the spindle via M function Flush gun Preparation for electronic dividing head, 4-axis "AC-2" Automatic universal swivel head / max. speed 3000 1/min. A and B axes each indexable by 5° - 72x72 positions Automatic tool changing and IKZ cooling through the spindle 20 bar Spindle holder BT 50 Automatic PICK UP for milling head rollers - 2 stations Y-axis extension at 800 mm (400 mm per side) Y-axis travel 3400 mm Chain tool changer 60-fold vertically changing Renishaw RMP-60 measuring probe for workpiece setup and testing Measuring probe cycles for Heidenhain TNC 640 installed

Datasheet

Request / Contact

milling machining centers - universal

- Knops Werkzeugmaschinen

- Konrad-Zuse-Straße 5

- 40789 Monheim

- Deutschland

-

02173 - 39494-0

02173 - 39494-29 -

maschinen@knops.de

www.knops.de

#1022-2257 · milling machining centers - universal

STARRAG-HECKERT - HEC 500 H/V Athletic - - 2008 - Siemens 840 D

Technical details

- CNC-control SIEMENS 840 D - portable handwheel - 2-station pallet changer - autom. horizontal-vertical milling head - 60-station ATC - coolant equipment with paper band filter - coolant thru spindle 80 bar - oil cooler - NC-rotary table 360 deg, type DA 500 EV - Chip conveyor Interference circle diameter 1150 mm

Datasheet

Request / Contact

Профиль трейдера: Knops Werkzeugmaschinen

GmbH & Co. KG

Связаться с торговцем

Наконечники для станков

GmbH & Co. KG

Конрад-Цузе-Штрассе 5

40789 - Монхайм

Германия

02173 - 39494-0">02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

GmbH & Co. KG

Конрад-Цузе-Штрассе 5

40789 - Монхайм

Германия

02173 - 39494-0">02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Профиль пользователя Trader

Knops Werkzeugmaschinen GmbH & Co. KG

Konrad-Zuse-Straße 5

Contact Trader

Knops Werkzeugmaschinen GmbH & Co. KG

Konrad-Zuse-Straße 5

40789 - Monheim

Deutschland

02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Contact person:

Konrad-Zuse-Straße 5

40789 - Monheim

Deutschland

02173 - 39494-0

02173 - 39494-29

maschinen@knops.de

www.knops.de

Contact person:

Machine category

4-Säulenpresse - Hydraulisch · Abkantpresse - hydraulisch · Aufspanntisch · Aufspannwinkel · Bandsägeautomat - Horizontal · Bearbeitungszentrum - Horizontal · Bearbeitungszentrum - Universal · Bearbeitungszentrum - Vertikal · Blechrundbiegemaschine - 3 Walzen · Blechrundbiegemaschine - 4 Walzen · Brennschneidemaschine · CNC Dreh- und Fräszentrum · Doppelständerpresse - Hydraulisch · Drehbarer Aufspanntisch · Drehmaschine - zyklengesteuert · Fahrständerfräsmaschine · Fixatoren · Flachschleifmaschine - Doppelständer · Flachschleifmaschine - Horizontal · Flachschleifmaschine - Vertikal · Fräseinrichtung · Innenschleifmaschine · Karusselldrehmaschine - Doppelständer · Koordinatenmessmaschine · Kühlmittelanlage · Lagertechnik · Leit- und Zugspindeldrehmaschine · Magnetspannplatte · Messmaschine · Plan- und Spitzendrehbank · Planscheibe · Portal - Bearbeitungszentrum · Portalfräsmaschine · Roboter - Handling · Rundschleifmaschine - Außen · Rundtaktmaschine · Rundtisch · Rundtischflachschleifmaschine - 2 Spind. · Schleifmaschinenzubehör · Schweißdrehtisch - rund · Schwerdrehmaschine · Senkerodiermaschine · Stangenlademagazin · Tafelschere - hydraulisch · Tieflochbohrmaschine · Werkzeug Voreinstellgerät · Werkzeugfräsmaschine - Universal · Werkzeughalter · Werkzeugschleifmaschine - Universal · Zahnrad-Abwälzfräsmaschine - vertikal · Zahnradschleifmaschine · Zubehör · Ölnebel-Abscheider ·